Dairy equipment

Through our professional skills and unremitting efforts

We provide you with cost-effective dairy processing plants, large-scale ranches, and supporting equipment

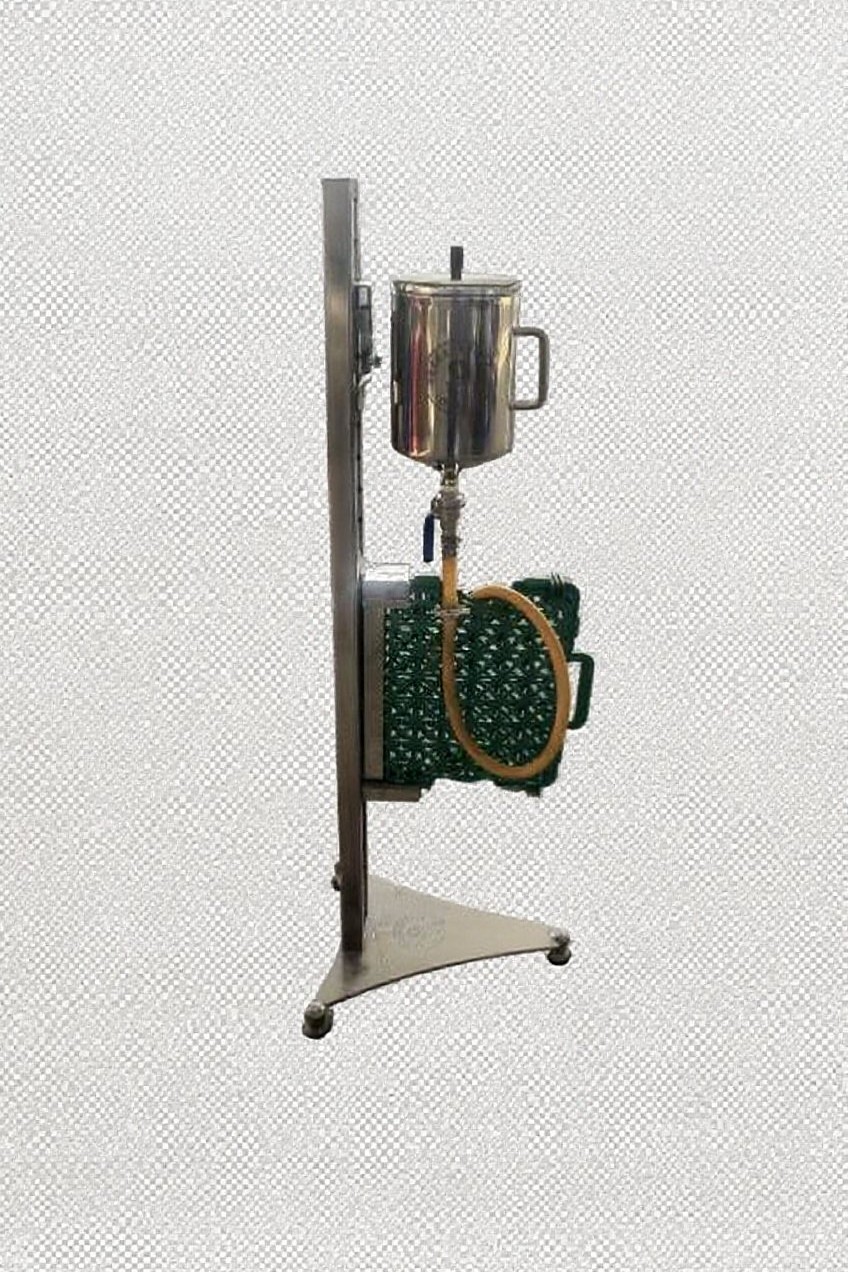

Pasteurization Machine

Our pasteurizer is of water bath type. Suitable to pasteurize colostrum and other fresh milk with good nutrition retention. Ideal choice for various farms and dairy cooperatives。

Product Features

1. This pasteurizeris uniquely structured, with external insulation, and made of 304-2B stainless steel.

2. Features large transition angle bend design for aesthetic appearance. Avoiddead corners in the equipment ,easy to clean and maintain.

3. Manufactured with a protectionfilm.Polished welding seams with passivation treatment.

4. Large volume allowssimultaneous processing of up to four pasteurizing baskets. Baskets are easy to load with robust stainless steel positioning buckles.

5. Controlsystemwith PLC and touchscreen. Features temperature control probes and level probes for one-touch operation, enabling automatic pasteurization and thawing.

6. Equipped with an electronic locktolock the machine cover during operation.

7. Flipping assist functionon the machine cover.

8. Drivingshaftswith special bearings for good lubrication, durability, and longevity.

9. Pasteurizingbaskets turn automatically with the shaftfor uniform heat distribution in the product, thus effective pasteurization.

Principle and Advantages of the Sterilizer

Product is heated to the sterilization temperature required (such as 137-140°C or 85-121°C) while it flowing through a tubular or plate heat exchanger, then maintained at this temperature for a certain time (4-5s or 15-22s) to reduce microorganisms or reach commercial sterility. The entire sterilization process is instantly completed at high temperatures, thoroughly killing microorganisms and spores that could cause spoilage and deterioration, while greatly preserving the original flavor and nutritional content of the food. This rigorous processing technique and precise handling method effectively prevent secondary contamination of food, significantly extending product shelf life. Both tubular sterilization system and plate sterilization system can be used for continuous sterilization processes of fruit and vegetable pulps, natural juices, concentrate juices, milk, fruit juice drinks, and other similar products.

- Canbe usedas liquid storage tank, mixing tank, blending tank, buffer tank, hot water tank etc..

- Mainly used in food, dairy, juice and beverage, pharmaceutical, chemicaland biotechnological industries.

- Features a double-shell structure with inner / outer barrels and polyurethane foaminginsulation material filled in between.

- 304-2B or 316 stainless steel platesmade.

- Ergonomically designed for easy operation.

- Conical endwith smoothrounded edge connect to the straight tank body.

- All transition sections oninternal wall are smooth shaped, sanitary design with no dead points forcleaning.

- Circular manhole.

- Various types of CIP cleaning devices.

- Breathing tubes to ensure atmospheric pressure inside the tank.

- Adjustable legs.

- Thermometer(onrequest).

- Ladders and guardrails (on request).

- Liquid level meteror liquid level control (on request).

- Anti-swirl plate.

Purpose

- Can be used as liquid storage tank, mixing tank, buffertank, blending tank, etc.

- Mainly used in food, dairy, juice and beverage, pharmaceutical, chemical and biotechnological industries.

Structure and Features

- Features a double-shell structurewith inner / outer barrels and polyurethane foaming insulation material filled in between.

- 304-2B or 316 stainless steel platesmade.

- Ergonomically designed for easy operation.

- Conical endwith smooth rounded edge connectto the straight tank body.

- All transition sections on internal wall are smooth shaped, sanitary design with no dead points for cleaning.

Tank Configuration

- Circular manhole.

- Varioustypesof CIP cleaning devices.

- Breathing tubes to ensure atmospheric pressure inside the tank.

- Adjustable legs.

- Thermometer (on request).

- Ladders and guardrails (on request).

- Liquid level meteror liquid level control (on request).

- Mixer.

- Anti-swirl plate.

Falling film evaporator heat up and boil low concentrate solution, to evaporate some of its moisture into vapor and achieve the purpose of concentrating. It’s an single-passage non-circulating evaporator with high efficiency. Its falling film principle ensures high heat transfer efficiency, minimal thermo-damage, short cooking time on product, low degradation trend, ease operation, low energy consumption, and compact dimension. It’s widely used for evaporation operations in chemical, pharmaceutical, light industry, food, petrochemical, and metallurgy sectors.

We design, manufacture, and install single, double, and multi-effect evaporators. We can also: Rebuild other types of evaporators into falling film evaporators, add thermo- pumps for normal evaporators to reduce steam consumption, supply various auxiliary equipment matching the evaporators, in order to meet the evaporation needs of various materials.

- Simple and convenient operation.

- Suitable for the evaporation of heat-sensitive products.

- High versatility.

- Lowenergy consumption and easy implementation of multi-effect operation.

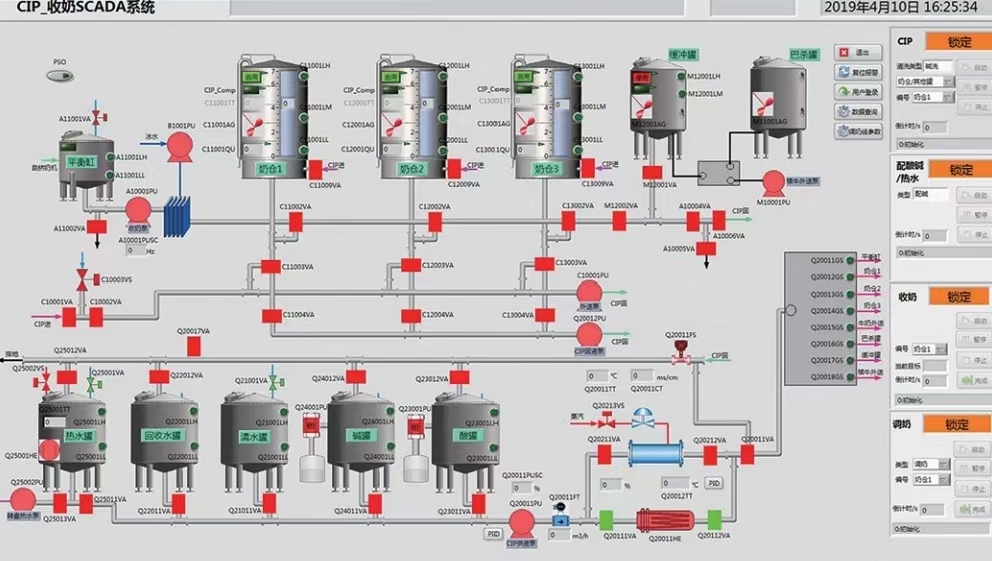

CIP Milk Collection Equipment and Control System CIP

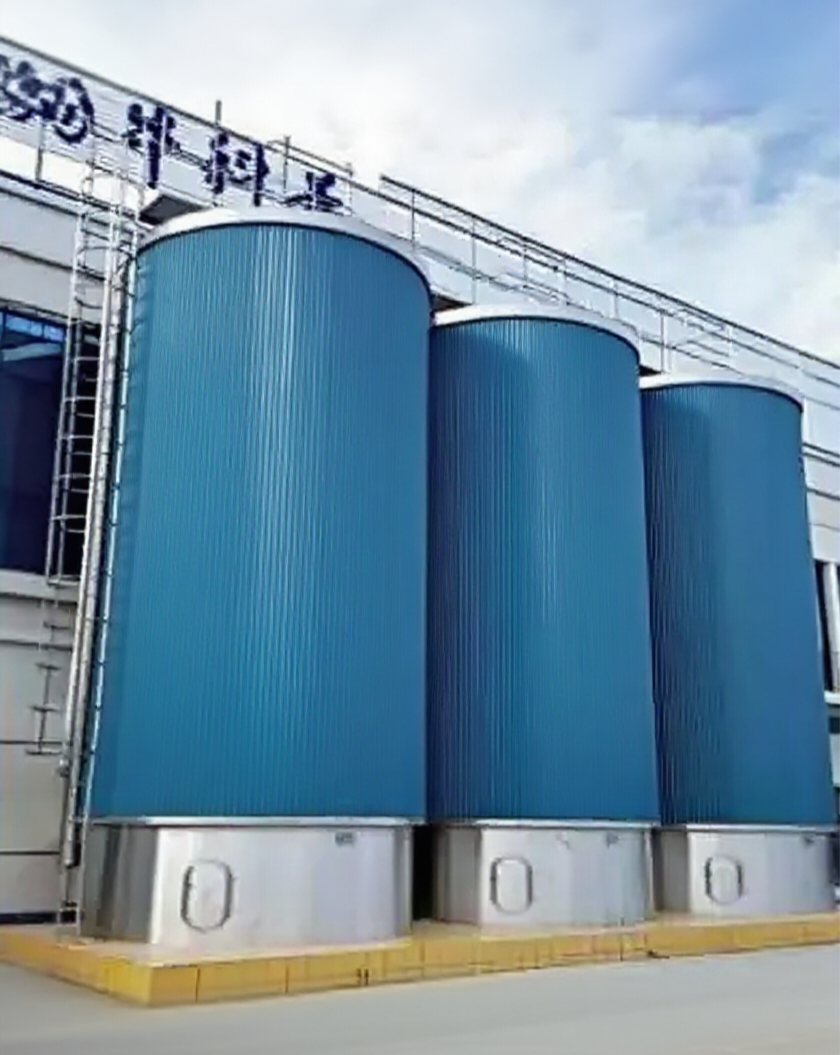

The milk silo is a stainless steel container used for low-temperature outdoor storage of fresh milk. Designed with external jacket filled up with insulation material, equipped with a high-speed push mixer for intermittent mixing. Allows low-temperature (≤5℃) fresh milk storage for 24 hours, with a temperature increase of no more than 2℃ without fat floating. Widely used for storing fresh milk in farm and dairy plants.

- Cylindrical double-shell structure, internal shell in contact withproductmade of 304-2B plate, external shell can be of 304-2B plate or paint corrugated plate on customer request;

- Equippedwith a side ladder and stainless steel platform with hand rail on the top, breathing tube, spray balls to clean tank breathing tube, drainage bowl, fork type high level detector. Integrated skirt and man-hole at the bottom;

- Witha transition chamber at the bottom of the silo, which is equipped with an elliptical man-hole, lateral mixer, digital thermometer, fork type level dtector, sampling valve, and mixer cleaning system;

- Polyurethanefoaminginsulation material is used to fill up the jacket of the silo.

We are able to design, manufacture, produce, and install milk storage silos ranging from 20T to 200T, with customized design on specific request.