Livestock equipment

Through our professional skills and unremitting efforts

We provide you with cost-effective dairy processing plants, large-scale ranches, and supporting equipment

Livestock equipment

Backflush Valve

Our backflush valve can be used in large, medium, and small farms. It can effectively improve sanitation conditions of the farm, enhance manure treatment efficiency, save water resource by recycling, and significantly reduce the labor intensity.

Our backflush valve can be used in large, medium, and small farms. It can effectively improve sanitation conditions of the farm, enhance manure treatment efficiency, save water resource by recycling, and significantly reduce the labor intensity.

- The body of the backflush valve is made of 304 stainless steel plate, bent and welded to achieve high strength, corrosion resistance, and a long lifespan. The valve core is made of anti-corrosionrubber material and features a tensionspring. The valve cover is composed of fixed and movable parts, equipped with a non-slip tread plate.

- Optimizedbending design ensures good sealing of valve bodyafter welding. Welding seams with passivation treatment achieves refined appearance.

- Cone shape water inlet on the valve body, with flangeconnection. Water outlet at 45° to the groundfor efficient water out flow.

- Silicone seal on inlet flange, ensure a watertight seal at the water inlet.

- Openable valve cover can open and close freely without obstruction.

- Valve cover and valve body are lined with a silicone seal strip to ensure an effective seal.

- Fixed valve coverfixedto the valve body by bolt for easy disassembly and maintenance.

- With compressed air introduced to the valve core through an air compressor to control the valve’s openand close. It can be programmed to open and close at set intervals, achievinghigh level of automation, reducing labor need with reduced workload.

Flushing Valve

Our flushing valves are suitable for large, medium, and small-sized farms, with advantages such as: a large diameter, corrosion resistance, reliability, durability, and ease for automatic control. Under specific working conditions, they shows significant advantage over other cast steel or cast-iron valves

1.Body of the flushing valve is made from 304 stainless steel, providing high strength and corrosion resistance, hencelong lifespan. The valve core is made of anti-corrosion rubber material and features a tension spring. The flat valve cover is sealed and fixed with bolt.

2.The valve body is roll-formed. Sealing by welding. Welding seams with passivation treatmentachievesrefined appearance.

3.Cone shape water inlet on the valve body, with flange connection. Water outlet at 90° to the inlet for efficient water outflow.

4.Silicone seal on inlet flange, ensure a watertight seal at the water inlet.

5.Valve cover and valve body are lined with a silicone seal strip to ensure an effective seal.

6.valve cover fixed to the valve body by bolt for easy disassembly and maintenance.

7.With compressed air introduced to the valve core through an air compressor to control the valve’s open and close. It can be programmed to open and close at set intervals, achieving high level of automation, reducing labor need with reduced workload.

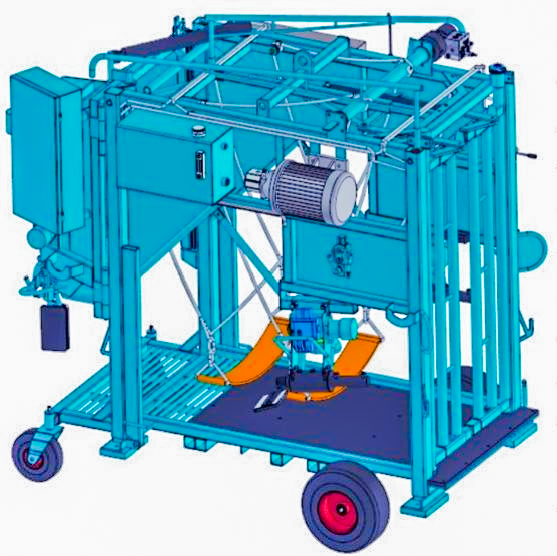

The BDJ-00 Working Chute is an equipment used to hold cattle in farms , which is convenient for dehorning, vaccination, and breeding,etc. With sturdy structure and simple operation, it can hold the cow all-around without any harm, ensuring the staff to complete the operation safely and efficiently.

Product Features:

1. Buckle-style self-locking door can be locked in any position.

2. Front door equipped with an adjustable cow head locking device.

3. Upper and lower swinging maintenance doors can be used seperately or together.

4. Agile sliding rear door that can be operated from either side of the chute.

5. Vet door opens in both direction for a full 180° maneuverability.

6. Two rows of rump locking system ensure safety regardless of cow size.

7. Operating handle switchable between left and right, providing convenient operation.

The cow bed loosening machine is powered by tractor PTO and assisted by a hydraulic lifting system. Crushing and scattering in motion. Crushed bedding fluffy and breathable. All blades are in manganese steel, sturdy and durable. Easy operateing,low failure rate. Common used in pastures.

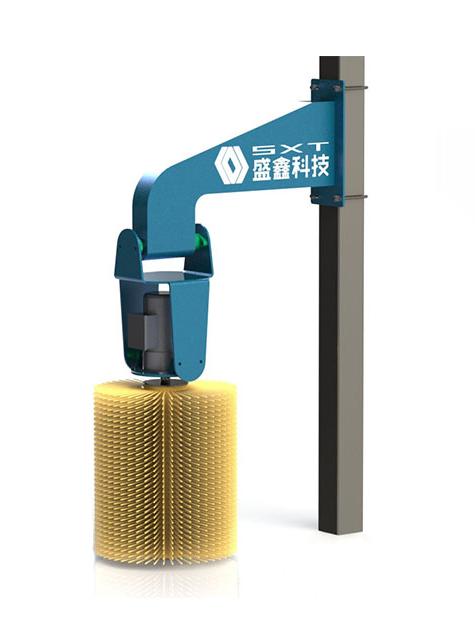

- Overload protection to prevent motor fromoverheating, IP55 protection level. Rotation startswhen the brush touches the cow and stops 10 seconds after the cow leave;

- The swingcow body brushcan touch more parts of the cow compared with other products, minimized operation and less barn space occupied;

- Easy installation, can be mounted on walls or columnsflexibly;

- Low energy consumption, easy to clean, suitable for 50-60 cowsper unit.

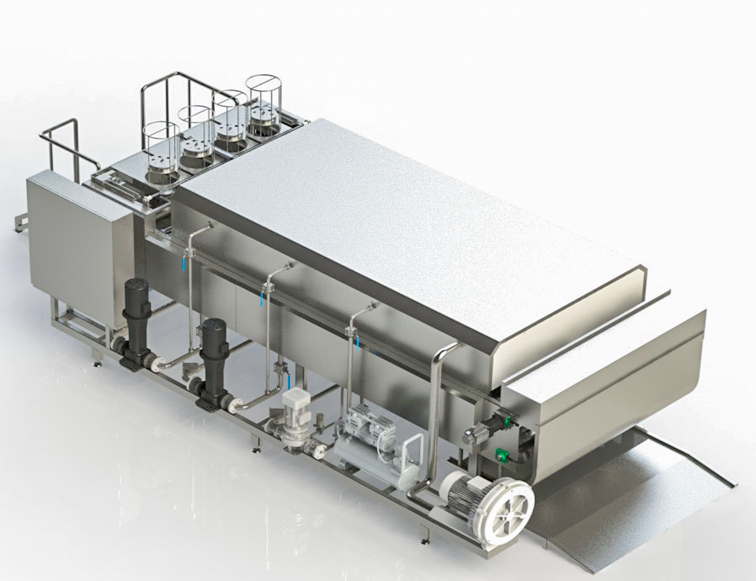

This device, driven by a chain powered by servo reduction motor, allows operators to simply push stacked feed buckets into an automatic dropping mechanism. The automatic drop mechanism is PLC-controlled. When the chain plate reaches a predetermined position, 4 feed buckets drop simultaneously, with their openings facing downwards. As the feed buckets rotate with the chain plate, they undergo pre-cleaning, diluted alkali solution cleaning, clean water rinsing, and finally high-pressure air blowing stage, finally drop along a rail into a pushing mechanism, which ejects the cleaned feed buckets. Cleaning process finish and ready for the next cycle.

With high automation level, this equipment greatly reduced manual labor needs for feed buckets cleaning. With its optimized cleaning process, cleaning solutions can be recycled, working costs are reduced, cleaning result is improved and cleanness of feed buckets are assured.

Structure and Features

1.tower-type structure, ensures complete mixing of the feed, hensea uniform blendingand complete feed moving.

2.Imported speedreducerdirectly coupleed with the auger, ensures sufficient mixing with less power.

3.Angurconstructed with thickened wear-resistant steel plates,robotic structure achieved.

4.Bottomof the storage bin inwear-resistant plates, while the rest in Q345 steel, extened life of equipment.

5.Bladescan be repositioned and usedagain when it is worn, thus extend the blade’s life.

6.Imported electronic weighing unit used in the weighing system, moreprecise feed formulationachieved.

General dimensions can be customized according to customer’s ranch.

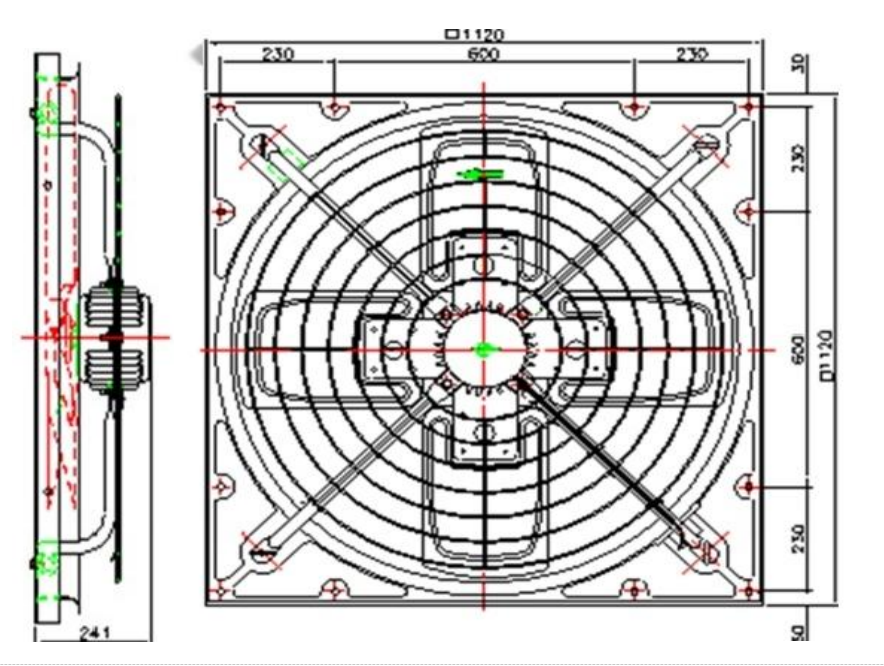

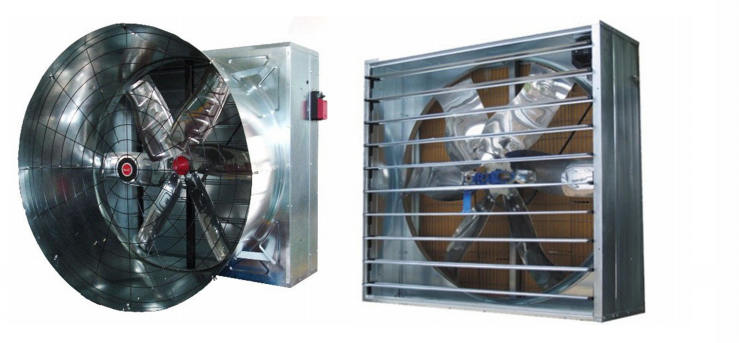

TFP-H100ET Farm Fan TFP-H10OET

S/N | Technical Parameter Name | Parameter |

1 | Fan Model | TFP-H100T |

2 | Brand | Shengxin Technology |

3 | Fan Blade Diameter | 1000mm |

4 | Power Supply | 3φ 50Hz 380V |

5 | Fan Frame Material | High-Quality Galvanized Plate |

6 | Fan Blade Material | Stainless Steel |

7 | Airflow | 20500(m³/h) |

8 | Drive Mode | Direct Drive Type |

9 | Fan Weight | 29Kg |

10 | Rotation Speed (RPM) | 700 |

11 | Number of Blades | 4 Blades |

12 | Motor Power (Load) | 420W |

13 | Air Pressure | 80 |

14 | Wind Speed at 6 Meters | 3 |

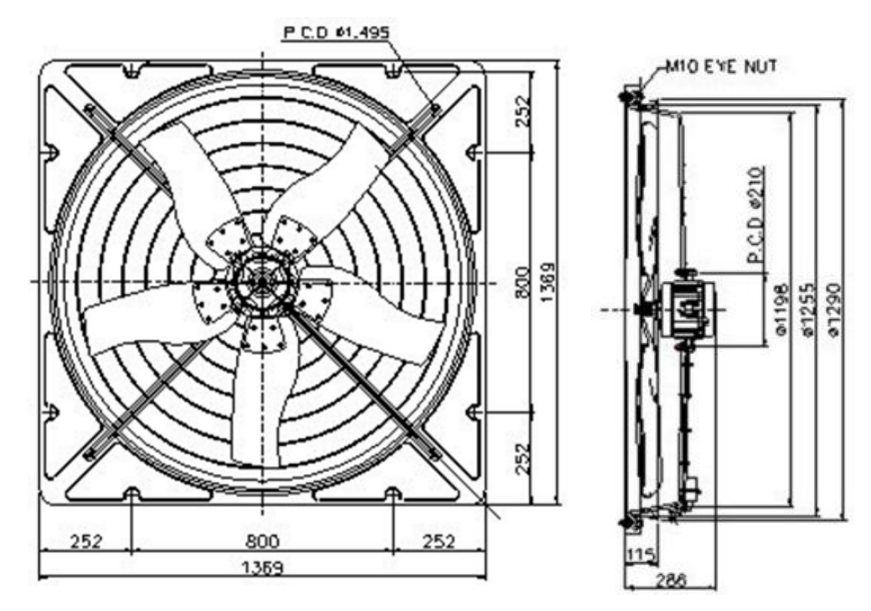

TFP-H120ET Farm Fan TFP-H12OET

S/N | Technical Parameter Name | Parameter |

1 | Fan Model | TFP-T120ET |

2 | Brand | Shengxin Technology |

3 | Fan Blade Diameter | 1200mm |

4 | Power Supply | 3φ 50Hz 380V |

5 | Fan Frame Material | High-Quality Galvanized Plate |

6 | Fan Blade Material | Aluminum |

7 | Airflow | 24500(m3/h) |

8 | Drive Mode | Direct Drive Type |

9 | Fan Weight | 38Kg |

10 | Rotation Speed (RPM) | 558 |

11 | Number of Blades | 5 Blades |

12 | Motor Power/Current (Load) | 480W/1.4A |

13 | Air Pressure | 80 |

14 | Wind Speed at 6 Meters | 4.5 |

TFH-H185ET Farm Fan TFH-H185ET

S/N | Technical Parameter Name | Parameter |

1 | Fan Model | TFH-F185ET |

2 | Brand | Shengxin Technology |

3 | Fan Blade Diameter | 1840mm |

4 | Power Supply

| 3φ 50Hz 380V |

5 | Fan Frame Material | Fiberglass |

6 | Fan Blade Material | Aluminum

|

7 | Airflow | 83400(m3/h) |

8 | Drive Mode | Belt Drive |

9 | Fan Weight | 200 |

10 | Rotation Speed (RPM) | 340 |

11 | Number of Blades | 6 |

12 | Motor Power (Load) | 2200W |

13 | Air Pressure | |

14 | Wind Speed at 6 Meters | 4 |

15 | Protection rating | IP55 |

16 | Insulation Level | F |

Farm Fan TFH-F127 & TFH-F127-CD

Blade | Airflow | Motor Power | Current | Noise | Air Pressure | Weight | Remarks |

(cm) | (m3/h) | (W) | (A) | (dB) | (Pa) | (Kg) | |

125 | 44,500 | 1100 | 2.8 | 70 | 70 | 112 | With Horn

|

Farm Fan TFH-F720ET

S/N | Technical Parameter Name | Parameter |

1 | Fan Model | TFH-F720ET |

2 | Brand | Shengxin Technology |

3 | Fan Blade Diameter | 7200mm |

4 | Power Supply | 3φ 50Hz 380V |

5 | Fan Frame Material | None |

6 | Fan Blade Material | Aviation Magnesium Aluminum Alloy |

7 | Airflow | 78000(m3/h) |

8 | Drive Mode | Direct Drive Type |

9 | Fan Weight | 130 |

10 | Rotation Speed (RPM) | 55 |

11 | Number of Blades | 6 |

12 | Motor Power (Load) | 1700W |

13 | Air Pressure | |

14 | Circulating Wind Speed | 2.5 |

15 | Protection rating | IP55 |

16 | Insulation Level | F |

The rotary grate decontaminator is mainly used for solid-liquid separation and is suitable for various wastewater pretreatment processes, such as pre-treatment of animal manure. It can also serve as a wastewater treatment facility for municipal wastewater treatment plants and residential communities. It is widely used in such industries as textiles, dyeing, and papermaking for solid-liquid separation.

This equipment is consist of driving system, frame, rake grate system, guide rail device, and electric control system. Cycloidal pinwheel reducer is used in the driving system with compact structure and high transmission efficiency. The rake tooth system comprises 3mm thickness stainless steel rake teeth, nylon sleeves, and sprocket roller chains. Assembling the rake teeth with the sleeve, nylon sleeve, and rake tooth shaft into a chain system, it is driven by the reducer through the sprocket and the spindle camshaft to lift debris from the wastewater. As the rake teeth rise with the chain’s movement, they flip over when reaching the top of the device, debris fall into the slag storage trough by gravity.

The rotary grate decontaminator designed and manufactured by our company has the following features:

1. Stainless steelmade, corrosion-resistant with low energy consumption and noise levels.

- With a slag discharge hopper for easy waste removal.

- Compact structure, simple and easy automatic control.

- Continuous decontamination process with clean slag discharge and high separation efficiency.

S/N | Item | ||

| 1 | Structural Type | Stand-up | |

| 2 | Dimensions (mm) | 2600×1780×2380 | |

| 3 | Equipment Weight (Kg) | 950 | |

| 4 | Matching Power (Kw) | 5.5 | |

| 5 | Lifting Height (mm) | 500 | |

| 6 | Fixed Plug Voltage | 220V | |

| 7 | Belly Band Lifting Brake | Yes | |

| 8 | Front Door Control | Hydraulic | |

| 9 | Rear Door Control | Hydraulic | |

| 10 | Front/Rear Hoof Lifting | Hydraulic | |

| 11 | Tray Flip Control | Hydraulic | |

- The fully hydraulic hoof trimmingchutemeets the requirements for any herd size and is specifically designed for 200-900kg cows. During the trimming process, cows experience no discomfort. All hydraulic components are designed and used to minimize the risk of injury to the cows. It has excellent stability. Once anchored with base bolts, it ensures the equipment stationary even if the cows are stressed.

- In holding phase, the cow is elevated off the ground by a hydraulic motor, which ensures balance of all four feet and the base of the hooves, effectively preventing feett injuries. Hydraulic brakesare alsoequipped for the safety of cows.

- The leg restraint uses a hydraulic motor capstan system for elevation and comes with a hydraulic-controlled hoof tray. This offers better comfort for cows under stress and protection duringtrimming. The holdingstability provideds trimmer a natural and clear view of the cow and their hooves, thus allowing the most accurate hoof trimming.

- Lifting height ≥500mm, adjustable for a comfort trimming of trimmer with different height.

- Once secured, easier to observe the states of hoof disease, ensuring thorough treatment of the disease.

- Equipped with an independent lighting system.

- The entrance for cows, both front and rear doors, are all manually open/closedthrough hydraulic system.

- Equipped withsafety protections for operators,emergency power-off switch, leakage protection and motor protection for device safety. Waterproof and dustproof.

- The total weight of the machine>900Kg.Lifting height ≥500mm. Noise levels ≤64dB.

- Operation and control system are hydraulic-based.

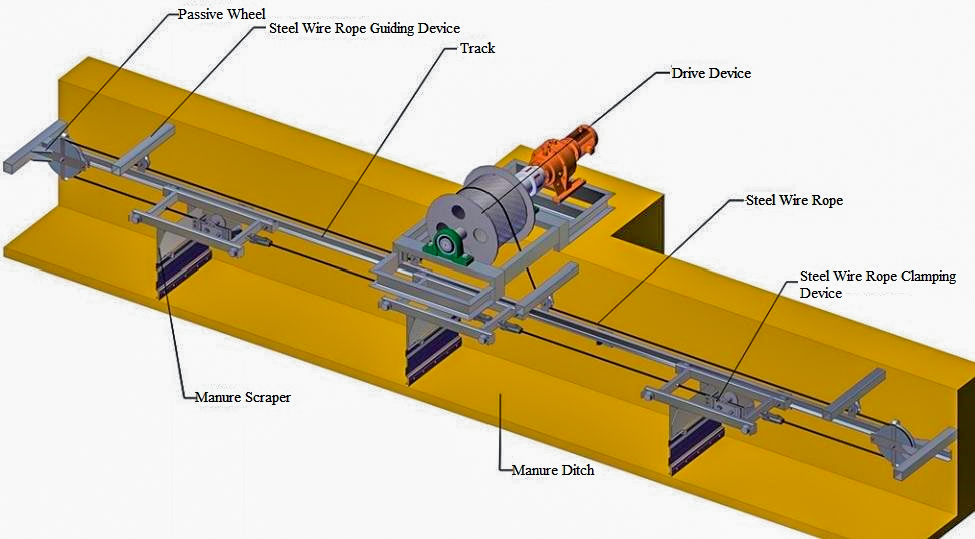

1. Manure ditch scraper speed adjustable according to site situation. 2. Overload protection; 3. Adjustable interval between forward and backward motion; 4. Acoustic and optical alarms; 5. Data monitoring and storage.

The control system of manure dip scraper’s is consists of touch screen, PLC, frequency converter, and other electronic components. By touch screen, possible to start or stop the manure scraper system in manual or automatic mode. Provided easy operation with flexible control.

In standby mode, inverter parameters could be set according to nominal parameters of the driving motor. Meanwhile relevant parameters could be set on the touch screen, such as: operating frequency value, overload current value, and delayed start value.

S/N | Item | Unit | Specification |

1 | Structural Type | Impeller Type | |

2 | Dimensions | mm | 1916×1304×6156 |

3 | Equipment Weight | Kg | 1300 |

4 | Fitted Power | Kw | 37 |

5 | Impeller Rotation Speed | r/min | 810 |

Working principle of FWB37-00 manure pump:

Powered by the electric motor, motion is transferred via the belt pulley to the main shaft and impeller. Liquid within the range of impeller moved by impleer. With centrifugal force, the liquid is expelled from the impeller along the tangent of it’s circumference to the outlet port. With liquid sent out, a low-pressure area forms near the pump casing’s rotating shaft. The liquid at the inlet is pushed into the pump by atmospheric pressure to fill the low-pressure area, forming a cyclical process. Then the manure is sucked into the pump body and discharged through the manure pipe to the designated location.

Features of FWB37-00 manure pump:

- Powerful, structurally rational, easy installation, and longlifespan.

- The impeller is made of wear-resistant material and has a cutting function to prevent objects from tangling.

- The lower transmission components adopt a multi-layer sealed lubrication structure, ensuring safe and reliable operation.

- The discharge pipe is designed with a checkvalve to prevent damagefrom the “water hammer” effect caused by backflow of manure.

S/N | Item | Unit | Specification |

1 | Structural Type | Impeller Type | |

2 | Dimensions | mm | 1376×805×6450 |

3 | Equipment Weight | Kg | 1300 |

4 | Fitted Power | Kw | 30 |

5 | Impeller Rotation Speed | r/min | 567 |

6 | Impeller Diameter | mm | 600 |

7 | Installation Height | mm | 5200 |

The rotating impeller, driven by the agitator, creates a vortex jet and axial thrust. Mixing is achieved with the shear force along the surface of the jet. With the friction, stirring action is induced to the liquid outside the flow field. Under the combined mixing, stirring, thrusting of the vortex jet and axial thrust, a volumetric flow is formed. By a large volume flow mode, the required water velocity and process flow field is achieved.

The FWJB30-00 type manure agitator has the following features:

- Powerful performance, rational structure, easy installation, and long lifespan.

- The impeller made of wear-resistant materialhas a cutting function to prevent tanglingby objects.

- Speedreducer withmulti-layer closed lubrication structure ensures safe and reliable operation.

- Direction of the impeller can be easilyadjusted throughadjustment rod on the top of the machine, in order to achieving multi-directional jet and thrust for better mixing effects.

Manure scraper system is installed inside the animal lanes. It removes the manure from the lanes into the manure ditches. Then the manure in the ditches is transferred into the collection tanks or manure storage facility by ditch scrapping device or water flushing system. Thanks to this automatic manure cleaning process, a lot of labor saved, manure processing efficiency significantly enhanced, barn sanitation improved, and hoof disorders and other diseases reduced.

1. Manure scraper speed adjustable according to site situation.

2. Overload protection;

3. Adjustable interval between forward and backward motion;

4. Acoustic and optical alarms;

5. Data monitoring and storage.

6. Multiple manure scrapers can be managed by single supervision computer.

- Special PE nozzle for Spray;

- Constant pressure water supply system, one for use, one for backup;

- Siemens PLC; Siemens/Profibus display;

- Danfoss frequency converter, variablefrequency water pumpof famous domestic brand;

- Signal transmission withstable and reliabledesign. Remote control on sprinkler system by central farm control system, with necessary data interface and protocol authorization.

- Special nylon sprinkler clamp, solid and durable, easynozzlereplacement.

Our water trough is made of stainless steel. It is equipped with a float valve, heating plate, temperature control probe, etc. Automatic water replenishment improves the hygienic conditions of cows’ drinking water, ensures water quality. Automatic heating system maintains water temperature for cows, ensures warm water even in cold winter. Reduced personnel need and their workload.

- Dual-layer structure in stainless steel with insulating material in between.

- Thoughtfully designed bending structure ensures a flawless assembly ofinner and outer shells. Trapezoid shape cross-section looks elegant and refined.

- Film-coated during fabrication.Low-current welded. Weld seams are polished followed by acid-washing and passivation.

- Float valveequipped for automatic water replenishment, leading to significant manual labor reducing and cost saving.

- The flip-top design of the float cover effectively ensures the float operates normally.

- Peating plate proper positioned for uniformwater heating inside the trough.

- Temperature control probe on the trough forautomatic heating and Enhanced water-drinking conditions for cattle.

Model | Specification | Dimensions (in mm) |

YSC-1.8×0.4 | 210L | 1838×520×367 |

YSC-3×0.4 | 360L | 3038×520×367 |

YSC-4×0.4 | 480L | 4038×520×367 |

Besides above water trough models, we can also tailor design and manufacture specific dimensioned water troughs according to the size of cattle shed.

Cow Headlocks

Freestalls

Gate

Calf Single Room

Calf Feeder

With the continuous growth of large-scale, intensive, and modern farms, calf feeders play a vital role in accelerating herd multiplication, farm cost reduction, and profit improving.

Our calf feeder can automatically stirs and heats under system control. It feeds calves through teats mounted outside the tank, can greatly reduce labor cost.

- Made of film protected 304-2B stainless steelplate, featuring a half opentop cover and polyurethane foaming insulation.

- Heating plate in the bottom of the tank with temperature sensor.

- Electric control cabinet on the top of the tank for automaticoperation. Automatic control on temperature and stirringfor uniform heating and preventing of milk clotting and pipe blocking.

- Recirculation and heat retention.

- Teats are directly mounted on the tank wall, with suction tubes extending to the bottom. Check-valve installed at the end of the suction tube.

Nominal Volume | Mixer Speed | Power | No. of Nipples |

180L | 18-260 rpm | 890W | 10 |

Calf Feeding cart

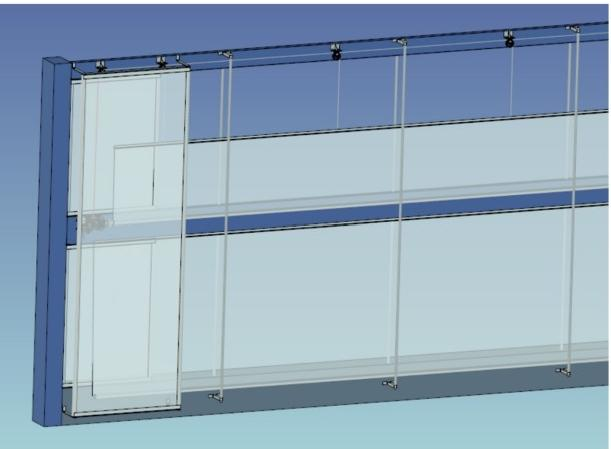

Farm Curtain

- Easy operation: Withpoweron, climbing movement of the electric rolling curtain can be controlled by press buttons. Meanwhile, the output shaft of the electric roller curtain drives the roller to release/wrap the roller cloth for reciprocating movement, thus realizing the closure or opening of the electric roller curtain, ultimately achieving the purpose of shading and ventilation.

- Environment-friendly: Withthe curtain’s functions for wind protection, moisture resistance, ventilation, and sunshade, the internal environment of the barn is improved, dairy cows’comfort enhanced, thus milk production increased.